Syrup yields not equal across all operation sizes

Generally, the data suggests that the larger maple operations will realize higher average yields than operations with fewer taps.

Showing 1 – 10 of 69 resources

Generally, the data suggests that the larger maple operations will realize higher average yields than operations with fewer taps.

Some seasons sometimes produce a bountiful crop of maple syrup. In other years producers are considerably less lucky. Periodic failures of the maple crop happen.

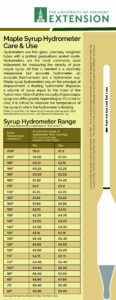

The University of Vermont Extension’s “New” temperature compensation chart syrup hydrometers.

New Temperature Compensation Chart for Syrup Hydrometers developed by the University of Vermont Extension

Because of the vertical orientation of the dominant anatomical feature of wood (vessels and fibers), sap within the stem of maple trees moves primarily in a vertical direction, either upward during as the tree is freezing/uptake phase or downward (mostly) during the thawing/exudation phase. When a tree is tapped, a zone of impermeable wood forms around the wood.

The University of Vermont (UVM) Proctor Maple Research Center (PMRC) in Underhill, Vermont, has along history of research on sap production. Maple syrup has been made at PMRC since shortly after its founding in 1946, in part for research and in part for demonstration. Syrup production has always been an important component of the work of PMRC as it keeps the faculty and staff aware of the issues involved in sap collection and syrup production, it provides more of a “buy in” from producers when they understand that we face the same hurdles as they do each season, and the revenue gained from the sale of maple syrup helps to fund the operation.

Avoiding tapping near previous tapholes is a common practice in maple production. This is because previous wounds create a zone of stained wood that extends slightly wider and deeper than the taphole, but extends upwards and downwards, often reaching 6-12 inches in length in each direction, affecting a volume of wood approximately 50 times (range of 15-150X) larger than the volume of the taphole (vanden Berg et al. 2023).

Business is booming if you own a commercial sugar bush! As forest managers, this means more and more of us are hearing from landowners interested in starting or maintaining a sugar bush. Unfortunately, if you are like us, you did not learn about maple syrup in forestry school. This episode’s guest, Mark Isselhardt, Extension Maple Specialist with the University of Vermont, helps us unpack the fundamentals of sap production, sugar bush management, and how the industry has changed in the 21st century.

Guidelines for tapping maple trees have existed for well over 100 years. Early tapping guidelines came about when buckets (gravity collection) were the only technology available for harvesting sap. New tapping guidelines are based on years of research into maple tree growth, sap harvesting practices/technology and a recognition that tree diameter alone does not fully explain all the factors that determine if tapping intensity in a given sugarbush is sustainable. This fact sheet presents sustainable tapping guidelines.

This research is focused on a first of its kind survey of professional foresters with the goal of not only understanding the technical approaches foresters use when working in sugarbushes, but also how the surveyed foresters view sugarbush management compared to managing stands for other forest products.